Hardware Sizes: Metric Screw Thread

This section contains tables of sizes for metric thread hardware.

Bolt Thread Sizes

The following table of thread sizes for coarse and fine pitch thread was created using the standard sizes from ASME B1.13M. Coarse pitch threads are preferred and should be used whenever possible, as stated in ASME B1.13M. The thread equations given previously for tensile stress area and for minor area were used in constructing the table.

The thread size designation for metric thread is given as "M[dia] x [pitch]". For example, a thread with a nominal diameter of 6 mm and a pitch of 1 mm is designated as "M6 x 1."

Nominal (Major)

Diameter [mm] |

|

Coarse Pitch |

|

Fine Pitch |

| Pitch [mm] |

Tensile Stress

Area [mm2] |

Minor

Area [mm2] |

Pitch [mm] |

Tensile Stress

Area [mm2] |

Minor

Area [mm2] |

| 1.6 |

0.35 |

1.270 |

1.076 |

--- |

--- |

--- |

| 2 |

0.4 |

2.073 |

1.789 |

--- |

--- |

--- |

| 2.5 |

0.45 |

3.391 |

2.980 |

--- |

--- |

--- |

| 3 |

0.5 |

5.031 |

4.473 |

--- |

--- |

--- |

| 3.5 |

0.6 |

6.775 |

6.000 |

--- |

--- |

--- |

| 4 |

0.7 |

8.779 |

7.750 |

--- |

--- |

--- |

| 5 |

0.8 |

14.18 |

12.68 |

--- |

--- |

--- |

| 6 |

1 |

20.12 |

17.89 |

--- |

--- |

--- |

| 8 |

1.25 |

36.61 |

32.84 |

1 |

39.17 |

36.03 |

| 10 |

1.5 |

57.99 |

52.29 |

1.25 |

61.20 |

56.30 |

| 12 |

1.75 |

84.27 |

76.25 |

1.25 |

92.07 |

86.04 |

| 14 |

2 |

115.4 |

104.7 |

1.5 |

124.5 |

116.1 |

| 16 |

2 |

156.7 |

144.1 |

1.5 |

167.2 |

157.5 |

| 20 |

2.5 |

244.8 |

225.2 |

1.5 |

271.5 |

259.0 |

| 24 |

3 |

352.5 |

324.3 |

2 |

384.4 |

364.6 |

| 30 |

3.5 |

560.6 |

519.0 |

2 |

621.2 |

596.0 |

| 36 |

4 |

816.7 |

759.3 |

2 |

914.5 |

883.8 |

| 42 |

4.5 |

1121 |

1045 |

2 |

1264 |

1228 |

| 48 |

5 |

1473 |

1377 |

2 |

1671 |

1629 |

| 56 |

5.5 |

2030 |

1905 |

2 |

2301 |

2252 |

| 64 |

6 |

2676 |

2520 |

2 |

3031 |

2975 |

| 72 |

6 |

3460 |

3282 |

2 |

3862 |

3799 |

| 80 |

6 |

4344 |

4144 |

1.5 |

4851 |

4798 |

| 90 |

6 |

5591 |

5364 |

2 |

6099 |

6020 |

| 100 |

6 |

6995 |

6740 |

2 |

7562 |

7473 |

| 110 |

--- |

--- |

--- |

2 |

9182 |

9084 |

Bolt Thread Dimensions

The following equations can be used to calculate dimensions for ISO metric threads. The thread profile is based on a parameter H, the height of the fundamental triangle. The value of H is related to the thread pitch, P by:

|

Equation, Metric Units [mm] |

Source |

| Minor Diameter |

dm.ext = dnom − 1.226869·P |

Shigley |

| Pitch Diameter |

|

Machinery's Handbook |

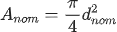

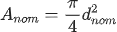

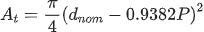

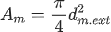

| Nominal Area |

|

|

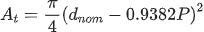

| Tensile Stress Area |

|

ASME B1.13M, Appendix B |

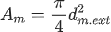

| Minor Area (Shear Area) |

|

|

In the table above, dnom is nominal diameter in millimeters and P is the thread pitch in millimeters.

Minimum Clearance Hole Diameters

The following table of clearance holes was adapted from ASME B18.2.8. The minimum hole diameters are given. This table also matches the table of recommended clearance holes from ASME B18.2.3.1M.

| Bolt Size |

Normal Fit [mm] |

Close Fit [mm] |

Loose Fit [mm] |

| M1.6 |

1.8 |

1.7 |

2 |

| M2 |

2.4 |

2.2 |

2.6 |

| –M2.5 |

2.9 |

2.7 |

3.1 |

| M3 |

3.4 |

3.2 |

3.6 |

| M4 |

4.5 |

4.3 |

4.8 |

| M5 |

5.5 |

5.3 |

5.8 |

| M6 |

6.6 |

6.4 |

7 |

| M8 |

9 |

8.4 |

10 |

| M10 |

11 |

10.5 |

12 |

| M12 |

13.5 |

13 |

14.5 |

| M14 |

15.5 |

15 |

16.5 |

| M16 |

17.5 |

17 |

18.5 |

| M20 |

22 |

21 |

24 |

| M24 |

26 |

25 |

28 |

| M30 |

33 |

31 |

35 |

| M36 |

39 |

37 |

42 |

| M42 |

45 |

43 |

48 |

| M48 |

52 |

50 |

56 |

| M56 |

62 |

58 |

66 |

| M64 |

70 |

66 |

74 |

| M72 |

78 |

74 |

82 |

| M80 |

86 |

82 |

91 |

| M90 |

96 |

93 |

101 |

| M100 |

107 |

104 |

112 |

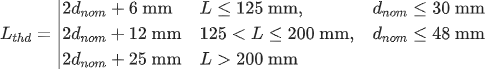

Bolt Thread Length

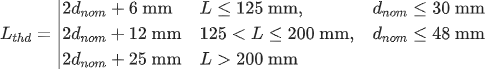

Per ASME B18.2.3.1M, Table 7, "Thread Lengths," the nominal thread length of metric bolts can be found by:

where L is the total bolt length and dnom is the nominal bolt diameter.

Hex Bolt Head Dimensions

The following table of hex bolt head dimensions was adapted from ASME B18.6.7M, Table 14, "Dimensions of Hex Head Machine Screws." This table is used for smaller size hardware.

Nominal Diameter and

Thread Pitch |

Width Across Flats |

Head Height |

| Minimum [mm] |

Maximum [mm] |

Minimum [mm] |

Maximum [mm] |

| M2 x 0.4 |

3.02 |

3.20 |

1.3 |

1.6 |

| M2.5 x 0.45 |

3.82 |

4.00 |

1.8 |

2.1 |

| M3 x 0.5 |

4.82 |

5.00 |

2.0 |

2.3 |

| M3.5 x 0.6 |

5.32 |

5.50 |

2.3 |

2.6 |

| M4 x 0.7 |

6.78 |

7.00 |

2.6 |

3.0 |

| M5 x 0.8 |

7.78 |

8.00 |

3.3 |

3.8 |

| M6 x 1 |

9.78 |

10.00 |

4.1 |

4.7 |

| M8 x 1.25 |

12.73 |

13.00 |

5.2 |

6.0 |

| M10 x 1.5 |

15.73 |

16.00 |

6.5 |

7.5 |

| M12 x 1.75 |

17.73 |

18.00 |

7.8 |

9.0 |

The following table of hex bolt head dimensions was adapted from ASME B18.2.3.1M, Table 3, "Dimensions of Hex Cap Screws."

Nominal Diameter and

Thread Pitch |

Width Across Flats |

Head Height |

| Minimum [mm] |

Maximum [mm] |

Minimum [mm] |

Maximum [mm] |

| M5 x 0.8 |

7.78 |

8.00 |

3.35 |

3.65 |

| M6 x 1 |

9.78 |

10 |

3.85 |

4.15 |

| M8 x 1.25 |

12.73 |

13.00 |

5.10 |

5.50 |

| M10 x 1.5 |

15.73 |

16.00 |

6.17 |

6.63 |

| M12 x 1.75 |

17.73 |

18.00 |

7.24 |

7.76 |

| M14 x 2 |

20.67 |

21.00 |

8.51 |

9.09 |

| M16 x 2 |

23.67 |

24.00 |

9.68 |

10.32 |

| M20 x 2.5 |

29.16 |

30.00 |

12.12 |

12.88 |

| M24 x 3 |

35.00 |

36.00 |

14.46 |

15.44 |

| M30 x 3.5 |

45.00 |

46.00 |

17.92 |

19.48 |

| M36 x 4 |

53.80 |

55.00 |

21.62 |

23.38 |

| M42 x 4.5 |

62.90 |

65.00 |

25.03 |

26.97 |

| M48 x 5 |

72.60 |

75.00 |

28.93 |

31.07 |

| M56 x 5.5 |

82.20 |

85.00 |

33.80 |

36.20 |

| M64 x 6 |

91.80 |

95.00 |

38.68 |

41.32 |

| M72 x 6 |

101.40 |

105.00 |

43.55 |

46.45 |

| M80 x 6 |

111.00 |

115.00 |

48.42 |

51.58 |

| M90 x 6 |

125.50 |

130.00 |

54.26 |

57.75 |

| M100 x 6 |

140.00 |

145.00 |

60.10 |

63.90 |

Hex Nut Dimensions

The following table of hex nut dimensions was adapted from ASME B18.2.4.1M, Table 1, "Dimensions of Hex Nuts, Style 1." For further reference, also see ASME B18.2.4.2M, Table 1, "Dimensions of Hex Nuts, Style 2.".

Nominal Diameter and

Thread Pitch |

Width Across Flats |

Head Height |

| Minimum [mm] |

Maximum [mm] |

Minimum [mm] |

Maximum [mm] |

| M1.6 x 0.35 |

3.02 |

3.20 |

1.05 |

1.30 |

| M2 x 0.4 |

3.82 |

4.00 |

1.35 |

1.60 |

| M2.5 x 0.45 |

4.82 |

5.00 |

1.75 |

2.00 |

| M3 x 0.5 |

5.32 |

5.50 |

2.15 |

2.40 |

| M3.5 x 0.6 |

5.82 |

6.00 |

2.55 |

2.80 |

| M4 x 0.7 |

6.78 |

7.00 |

2.90 |

3.20 |

| M5 x 0.8 |

7.78 |

8.00 |

4.40 |

4.70 |

| M6 x 1 |

9.78 |

10.00 |

4.90 |

5.20 |

| M8 x 1.25 |

12.73 |

13.00 |

6.44 |

6.80 |

| M10 x 1.5 |

15.73 |

16.00 |

8.04 |

8.40 |

| M12 x 1.75 |

17.73 |

18.00 |

10.37 |

10.80 |

| M14 x 2 |

20.67 |

21.00 |

12.10 |

12.80 |

| M16 x 2 |

23.67 |

24.00 |

14.10 |

14.80 |

| M20 x 2.5 |

29.16 |

30.00 |

16.90 |

18.00 |

| M24 x 3 |

35.00 |

36.00 |

20.20 |

21.50 |

| M30 x 3.5 |

45.00 |

46.00 |

24.30 |

25.60 |

| M36 x 4 |

53.80 |

55.00 |

29.40 |

31.00 |

Internal Thread Dimensions

The following equations can be used to calculate internal thread dimensions for ISO metric threads

|

Equation, Metric Units [mm] |

Source |

| Minor Diameter |

dm.int = dnom − 1.25·H = dnom − 1.08253175·P |

Machinery's Handbook |

| Pitch Diameter |

dp.int = dnom − 0.75·H = dnom − 0.64951905·P |

Machinery's Handbook |

In the table above, dnom is nominal diameter in millimeters and P is the thread pitch in millimeters.

Flat Washer Dimensions

The following table of flat washer dimensions was adapted from ASME B18.22M, Table 1, "Dimensions of Metric Plain Washers (General Purpose)." Plain washers come in 3 series: Regular, Narrow, and Wide.

| Nominal Size |

Series |

Inner Diameter |

Outer Diameter |

Thickness |

| Min [mm] |

Max [mm] |

Min [mm] |

Max [mm] |

Min [mm] |

Max [mm] |

| M1.6 |

Narrow |

1.95 |

2.09 |

3.70 |

4.00 |

0.50 |

0.70 |

| M1.6 |

Regular |

1.95 |

2.09 |

4.70 |

5.00 |

0.50 |

0.70 |

| M1.6 |

Wide |

1.95 |

2.09 |

5.70 |

6.00 |

0.60 |

0.90 |

| M2 |

Narrow |

2.50 |

2.64 |

4.70 |

5.00 |

0.60 |

0.90 |

| M2 |

Regular |

2.50 |

2.64 |

5.70 |

6.00 |

0.60 |

0.90 |

| M2 |

Wide |

2.50 |

2.64 |

7.64 |

8.00 |

0.60 |

0.90 |

| M2.5 |

Narrow |

3.00 |

3.14 |

5.70 |

6.00 |

0.60 |

0.90 |

| M2.5 |

Regular |

3.00 |

3.14 |

7.64 |

8.00 |

0.60 |

0.90 |

| M2.5 |

Wide |

3.00 |

3.14 |

9.64 |

10.00 |

0.80 |

1.20 |

| M3 |

Narrow |

3.50 |

3.68 |

6.64 |

7.00 |

0.60 |

0.90 |

| M3 |

Regular |

3.50 |

3.68 |

9.64 |

10.00 |

0.80 |

1.20 |

| M3 |

Wide |

3.50 |

3.68 |

11.57 |

12.00 |

1.00 |

1.40 |

| M3.5 |

Narrow |

4.00 |

4.18 |

8.64 |

9.00 |

0.80 |

1.20 |

| M3.5 |

Regular |

4.00 |

4.18 |

9.64 |

10.00 |

1.00 |

1.40 |

| M3.5 |

Wide |

4.00 |

4.18 |

14.57 |

15.00 |

1.20 |

1.75 |

| M4 |

Narrow |

4.70 |

4.88 |

9.64 |

10.00 |

0.80 |

1.20 |

| M4 |

Regular |

4.70 |

4.88 |

11.57 |

12.00 |

1.00 |

1.40 |

| M4 |

Wide |

4.70 |

4.88 |

15.57 |

16.00 |

1.60 |

2.30 |

| M5 |

Narrow |

5.60 |

5.78 |

10.57 |

11.00 |

1.00 |

1.40 |

| M5 |

Regular |

5.60 |

5.78 |

14.57 |

15.00 |

1.20 |

1.75 |

| M5 |

Wide |

5.60 |

5.78 |

19.48 |

20.00 |

1.60 |

2.30 |

| M6 |

Narrow |

6.65 |

6.87 |

12.57 |

13.00 |

1.20 |

1.75 |

| M6 |

Regular |

6.65 |

6.87 |

18.28 |

18.80 |

1.20 |

1.75 |

| M6 |

Wide |

6.65 |

6.87 |

24.88 |

25.40 |

1.60 |

2.30 |

| M8 |

Narrow |

8.90 |

9.12 |

18.28 |

18.80 |

1.60 |

2.30 |

| M8 |

Regular |

8.90 |

9.12 |

24.88 |

25.40 |

1.60 |

2.30 |

| M8 |

Wide |

8.90 |

9.12 |

31.38 |

32.00 |

2.00 |

2.80 |

| M10 |

Narrow |

10.85 |

11.12 |

19.48 |

20.00 |

1.60 |

2.30 |

| M10 |

Regular |

10.85 |

11.12 |

27.48 |

28.00 |

2.00 |

2.80 |

| M10 |

Wide |

10.85 |

11.12 |

38.38 |

39.00 |

2.50 |

3.50 |

| M12 |

Narrow |

13.30 |

13.57 |

24.88 |

25.40 |

2.00 |

2.80 |

| M12 |

Regular |

13.30 |

13.57 |

33.38 |

34.00 |

2.50 |

3.50 |

| M12 |

Wide |

13.30 |

13.57 |

43.38 |

44.00 |

2.50 |

3.50 |

| M14 |

Narrow |

15.25 |

15.52 |

27.48 |

28.00 |

2.00 |

2.80 |

| M14 |

Regular |

15.25 |

15.52 |

38.38 |

39.00 |

2.50 |

3.50 |

| M14 |

Wide |

15.25 |

15.52 |

49.38 |

50.00 |

3.00 |

4.00 |

| M16 |

Narrow |

17.25 |

17.52 |

31.38 |

32.00 |

2.50 |

3.50 |

| M16 |

Regular |

17.25 |

17.52 |

43.38 |

44.00 |

3.00 |

4.00 |

| M16 |

Wide |

17.25 |

17.68 |

54.80 |

56.00 |

3.50 |

4.60 |

| M20 |

Narrow |

21.80 |

22.13 |

38.38 |

39.00 |

3.00 |

4.00 |

| M20 |

Regular |

21.80 |

22.32 |

49.00 |

50.00 |

3.50 |

4.60 |

| M20 |

Wide |

21.80 |

22.32 |

64.80 |

66.00 |

4.00 |

5.10 |

| M24 |

Narrow |

25.60 |

26.12 |

43.00 |

44.00 |

3.50 |

4.60 |

| M24 |

Regular |

25.60 |

26.12 |

54.80 |

56.00 |

4.00 |

5.10 |

| M24 |

Wide |

25.60 |

26.12 |

70.80 |

72.00 |

4.50 |

5.60 |

| M30 |

Narrow |

32.40 |

33.02 |

54.80 |

56.00 |

4.00 |

5.10 |

| M30 |

Regular |

32.40 |

33.02 |

70.80 |

72.00 |

4.50 |

5.60 |

| M36 |

Narrow |

38.30 |

38.92 |

64.80 |

66.00 |

4.50 |

5.60 |

| M36 |

Regular |

38.30 |

38.92 |

88.60 |

90.00 |

5.00 |

6.40 |

| M36 |

Wide |

38.30 |

38.92 |

108.60 |

110.00 |

7.00 |

8.50 |

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist

Pipe Extrusion Engineering Specialist